DTF Durability, a cutting-edge printing method, directly applies designs to fabric using heat and pressure, eliminating extra coatings. It offers increased longevity, vibrant color reproduction on various fabrics, and versatility for diverse apparel items. Selecting high-quality cotton or polyester blends ensures structural integrity, breathability, and lasting prints. Specialized DTF inks enhance adhesion on darker fabrics, preventing fading. Professional application involves a clean surface, precise positioning, and consistent heat pressure using a heat press or applicator tool.

Learn how to apply DTF durability like a pro with our comprehensive guide. Discover the fundamentals and immense benefits of this cutting-edge technology, from enhanced protection to extended product life. We’ll walk you through choosing robust materials and mastering application techniques for optimal DTF performance. Elevate your craftsmanship and ensure long-lasting results with these essential insights on DTF durability.

- Understanding DTF Durability: Basics and Benefits

- Choosing the Right Materials for Longevity

- Application Techniques for Optimal DTF Performance

Understanding DTF Durability: Basics and Benefits

Understanding DTF Durability: Basics and Benefits

DTF (Direct to Fabric) durability is a game-changing technique in the world of custom t-shirt printing. It involves applying designs directly onto the fabric using heat and pressure, eliminating the need for additional coatings or finishes. This innovative process offers a range of benefits that make it a top choice for both professionals and enthusiasts in the apparel industry. One of its key advantages is enhanced longevity; DTF printing ensures that ink becomes part of the fabric fibers, making designs resistant to fading, cracking, or peeling over time.

Furthermore, DTF durability allows for vibrant, indelible colors and intricate detail reproduction on various fabrics, including cotton, polyester, and blends. The process is versatile, accommodating not just custom t-shirts but also sweatshirts, hats, and other apparel items. With its ability to produce high-quality, long-lasting results, DTF printing has revolutionized the way we personalize and mass-produce garments, ensuring that designs remain intact even under rigorous use or frequent washing.

Choosing the Right Materials for Longevity

When aiming for long-lasting DTF Durability, selecting the appropriate materials is a fundamental step. The key to achieving longevity in custom t-shirts or direct to film personalized hoodies lies in understanding fabric composition and its interaction with the DTF printing process. Opting for high-quality, durable fabrics such as cotton or polyester blends ensures a robust foundation for your designs. These materials offer excellent breathability while maintaining their structure even after repeated washes, ensuring your prints remain vibrant and intact.

Furthermore, considering the type of ink used in DTF printing for dark fabrics is crucial. Specialized inks designed for darker garments can provide superior adhesion and color fastness, preventing fading or smudging over time. This attention to material selection guarantees that your custom creations not only look amazing initially but also maintain their aesthetic appeal for years to come.

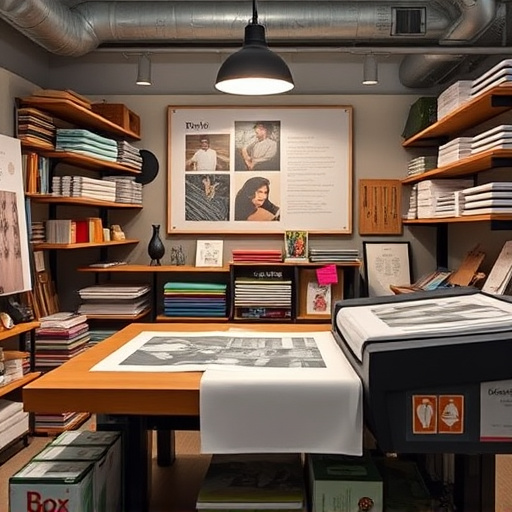

Application Techniques for Optimal DTF Performance

Applying DTF (Direct to Fabric) durability like a pro requires understanding and utilizing specific techniques for optimal performance. For best results, start by ensuring your work surface is clean, flat, and free from debris. This foundation is crucial for achieving precise alignment during the application process. Next, carefully position the dtf transfers onto the fabric, paying close attention to the design details and ensuring no air bubbles are trapped beneath. A heat press is a game-changer in this regard, allowing you to apply consistent pressure and heat, fusing the transfer permanently onto the fabric without damaging its integrity.

Once positioned, activate the heat press at the recommended temperature for your specific dtf transfers (typically around 350°F or 175°C). Maintain pressure for the specified time, usually between 15-30 seconds, depending on the material and transfer type. After the application, allow the fabric to cool down before removing the heat press. For cold peel dtf transfers, skip the heat press and simply adhere the transfer using a precision applicator tool, following the manufacturer’s instructions for optimal adhesion and long-lasting durability.

DTF durability is a game-changer for professionals seeking long-lasting, high-performance finishes. By understanding its basics and benefits, choosing suitable materials, and mastering application techniques, you can achieve exceptional results. Incorporating DTF into your toolkit ensures lasting protection and enhances the tapestry of surface treatments available to you. Remember, with the right approach, DTF durability is not just an option but a surefire way to revolutionize your projects.